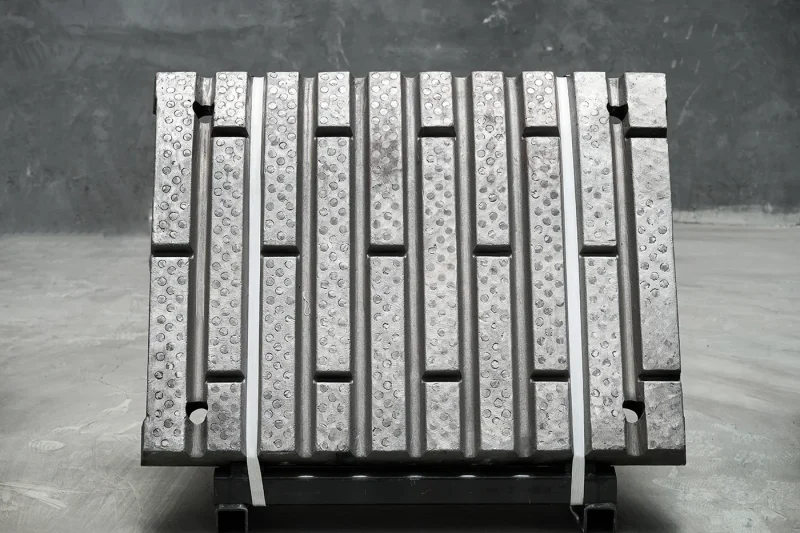

The way we incorporate titanium inlays is much different than other traditional suppliers. Titanium carbide jaw plates are less impact-resistant than steel jaw plates, which helps in the crushing operation.

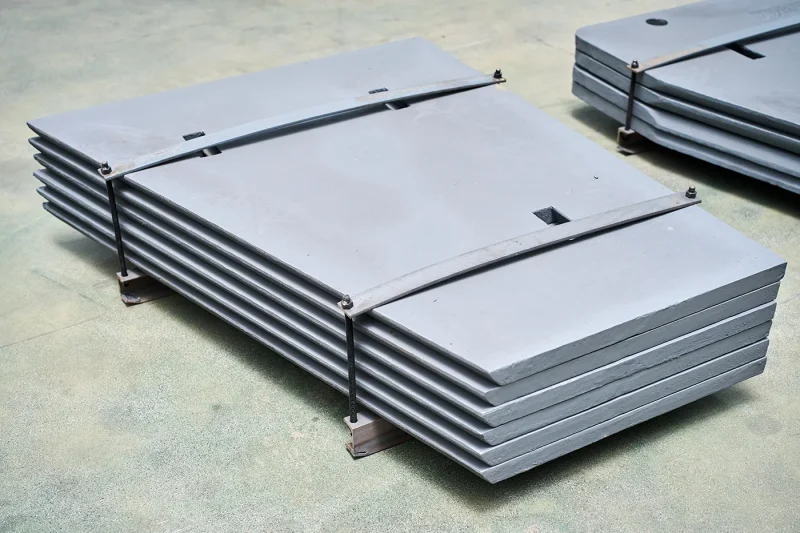

After examining and matching with machinery specifics, we create complex inlays to fully augment and assist machinery operations. Once our team has investigated your machinery and operation personnel in-depth, they will determine where to apply the titanium carbide plates based on the liner’s maximum wear zone.

The Benefits of Using Titanium Carbide as Crusher Jaw Plates;

- Versatile and can easily be customized for machinery locality and work conditions

- Offers maximum wear time and durability around manganese steel