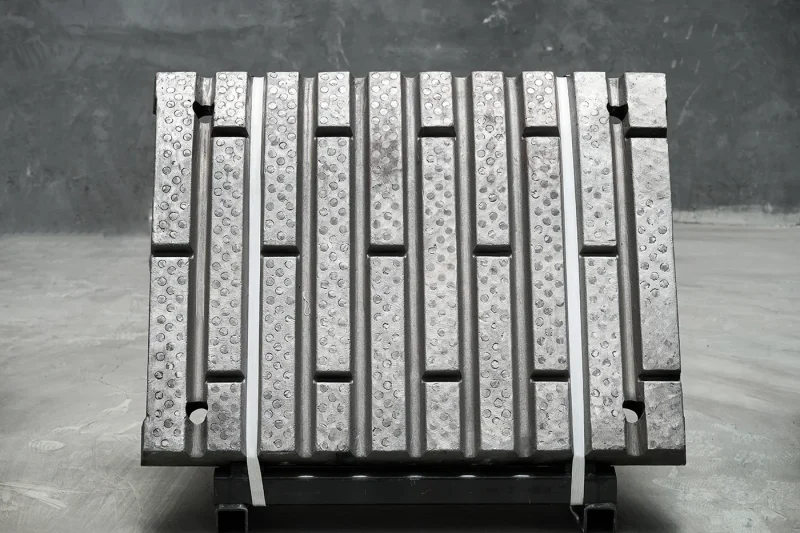

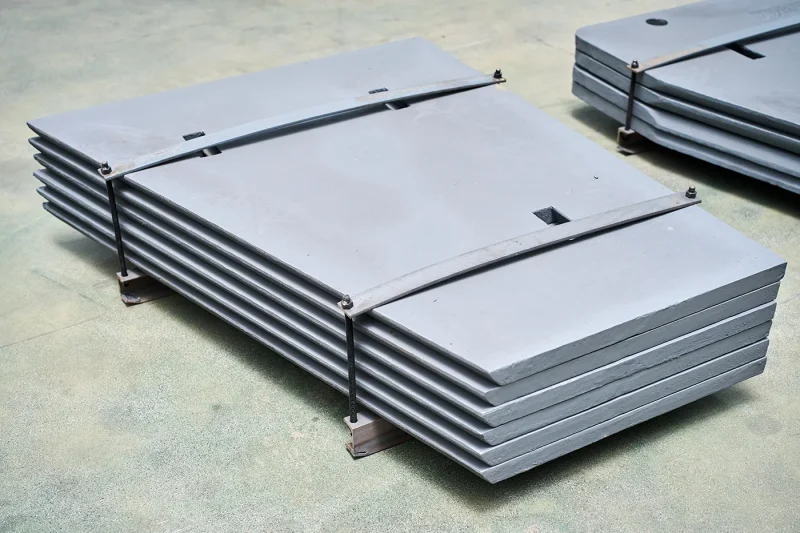

Jaw Plates Cast for Maximum Performance

Shengda jaw plates are built to deliver outstanding wear life, consistent crushing efficiency, and reliable performance in even the toughest applications. Each plate is cast to OEM standards, refined through advanced heat-treatment processes, and finished with precision machining—ensuring a perfect fit and optimized material reduction from the moment it’s installed.

Backed by decades of industry experience, Shengda has supplied hundreds of jaw plate designs across multiple brands and models. With a deep inventory of patterns and molds for the most widely used crushers, we’re able to shorten lead times and deliver faster.